Benefits of Air Conditioning in Grow Tents: Your Complete Climate Control Solution

Air conditioning transforms challenging grow tent environments into precisely controlled growing paradises. While many growers rely solely on ventilation and passive cooling, dedicated AC units provide unmatched temperature stability, humidity control, and year-round growing consistency that separates amateur harvests from professional results.

Understanding when air conditioning becomes necessary—and how it delivers benefits beyond simple cooling—helps you make informed decisions about investing in climate control equipment. From preventing heat stress during summer to maintaining optimal VPD throughout flowering, the right AC setup can dramatically improve both plant health and final yields.

Understanding the Role of Air Conditioning in Grow Tents

Air conditioning serves multiple critical functions beyond simple temperature reduction. Modern AC units simultaneously cool air, remove excess humidity, filter particulates, and create consistent environmental conditions that ventilation alone cannot achieve. This multi-functional capability makes AC especially valuable in challenging growing situations.

Temperature stability represents AC's primary benefit. While fans and ventilation can manage minor heat fluctuations, air conditioning maintains precise temperature ranges regardless of external conditions. This consistency prevents the temperature swings that stress plants, disrupt metabolic processes, and reduce yields.

Dehumidification occurs naturally during the AC cooling process. As warm, moist air passes over cold evaporator coils, water vapor condenses and drains away, effectively removing humidity without requiring separate dehumidifier equipment. This dual-action benefit proves especially valuable during flowering when high humidity threatens bud quality.

Air filtration through AC systems removes dust, pollen, and airborne contaminants that can harbor pests or disease. While not a replacement for proper ventilation and filtration, AC contributes to overall air quality maintenance that supports healthier plants and cleaner growing environments. Learn more about optimal conditions in our guide on maintaining ideal grow room temperatures.

When Air Conditioning Becomes Necessary

Hot summer conditions overwhelm passive cooling in most climates. When ambient temperatures exceed 85°F, ventilation simply circulates hot air without adequate cooling. Air conditioning becomes essential when you can't source cool intake air or when exhaust systems can't remove heat fast enough to maintain optimal temperatures.

High-intensity lighting generates substantial heat that ventilation alone often cannot manage. Multiple LED fixtures in larger tents or HID systems in any size space create heat loads requiring active cooling. If your grow lights raise tent temperatures above 85°F during operation despite maximum ventilation, air conditioning provides the solution.

Dense plant canopies trap heat and humidity, creating microclimates that promote mold and disease even when overall tent conditions seem acceptable. Air conditioning's combination of cooling and dehumidification penetrates these problem zones more effectively than simple air circulation, preventing the localized humidity spikes that cause bud rot. For more on humidity management, see our comprehensive guide on reducing humidity in grow tents.

Year-round consistency matters for perpetual harvest operations where maintaining identical conditions across multiple grow cycles ensures predictable results. Seasonal temperature variations force compromises without AC—running lights at night in summer, accepting suboptimal temperatures in winter. Air conditioning eliminates these seasonal limitations, enabling true year-round production.

Basement or garage grows face unique challenges from external temperature extremes, poor insulation, and limited natural climate moderation. These spaces benefit enormously from air conditioning's ability to create stable microclimates independent of surrounding conditions.

Temperature Control Benefits

Precise temperature management maximizes photosynthesis efficiency and metabolic processes. Plants perform best within narrow temperature ranges—typically 70-85°F during vegetative growth and 65-80°F during flowering. Air conditioning maintains these exact ranges consistently, enabling plants to function at peak efficiency throughout their lifecycle.

Heat stress prevention protects your investment and yields. Temperatures exceeding 85°F trigger stress responses that slow growth, reduce flowering, and diminish final quality. Prolonged heat exposure can cause permanent damage including leaf burn, wilted growth, and hermaphroditism in sensitive plants. AC prevents these devastating outcomes entirely.

Nighttime temperature control improves plant development and prevents morning condensation. Many growers overlook night temperatures, but proper dark-period cooling enhances flower development and prevents the humidity spikes that occur when warm lights-on air meets cool surfaces during lights-off periods. Explore more strategies in our article on keeping grow tents cool.

Consistent temperature enables optimal nutrient uptake and water transportation. Plants evolved to function within specific temperature windows where enzymatic processes and cellular transport mechanisms work most efficiently. Temperature fluctuations disrupt these processes, reducing growth rates even when averages seem acceptable. AC-maintained stability keeps plants operating at peak metabolic efficiency.

Seasonal independence eliminates compromises forced by external weather. Summer growers without AC either accept reduced yields from heat stress or invest in elaborate cooling solutions. Winter growers waste heating energy combating ventilation heat loss. Air conditioning creates controllable microclimates regardless of season, enabling consistent production quality year-round.

Humidity Management Advantages

Dual-action climate control through simultaneous cooling and dehumidification provides superior environmental management compared to addressing temperature and humidity separately. Every BTU of cooling capacity removes specific amounts of moisture, with typical residential AC units extracting 2-4 pints of water per hour of operation. This natural dehumidification often eliminates the need for dedicated dehumidifier equipment.

Flowering stage protection becomes critical as dense bud development creates humidity traps within the canopy. Late flowering requires 30-40% relative humidity to prevent bud rot, mold, and mildew—conditions difficult to maintain without AC's combined cooling and moisture removal. The alternative—running dehumidifiers alongside cooling fans—consumes more energy while providing less consistent results.

VPD optimization through precise humidity control maximizes growth rates and yield potential. Vapor Pressure Deficit represents the relationship between temperature, humidity, and plant transpiration—the "sweet spot" where plants breathe optimally. AC enables precise VPD management impossible with ventilation-only systems. Learn more in our detailed guide on lowering VPD in grow tents.

Condensation prevention protects equipment and plants from moisture damage. When warm, humid air contacts cold surfaces—tent walls, ducting, light fixtures—water condenses, dripping onto plants and creating rust or electrical hazards. AC reduces humidity before air contacts cold surfaces, eliminating condensation formation that plagues ventilation-only systems.

Mold and mildew prevention saves crops from devastating losses. High humidity environments breed fungal diseases that can destroy entire grows within days. Once established, mold spreads rapidly and proves nearly impossible to eliminate mid-cycle. AC's humidity control prevents these outbreaks entirely rather than fighting symptoms after problems develop.

Energy Efficiency and Cost Considerations

Modern mini-split systems deliver remarkable efficiency compared to portable AC units or window installations. Mini-splits achieve SEER ratings of 18-30, using 30-50% less electricity than comparable portable units while providing superior temperature control and humidity removal. The higher initial investment pays back through lower operating costs and longer equipment life.

Strategic cooling reduces overall energy consumption by enabling more efficient ventilation. Properly sized AC allows slower fan speeds and less frequent air exchanges, reducing electricity used by ventilation equipment while maintaining better environmental conditions. This synergistic efficiency often costs less than running high-speed fans continuously trying to manage heat through ventilation alone.

Heat recovery in winter climates transforms wasted cooling capacity into usable warmth. Dual-purpose mini-split systems provide both cooling and heating, using heat pump technology to warm grow spaces efficiently during cold months. This dual functionality maximizes equipment value in climates experiencing both seasonal extremes.

Equipment longevity justifies premium investments. Quality mini-split systems last 15-20 years with proper maintenance versus 5-7 years for portable units. When calculated over lifespan, mini-splits cost significantly less per year while delivering superior performance throughout their service life.

Yield improvements offset equipment costs rapidly. The combination of optimal temperatures and controlled humidity typically increases yields 20-40% compared to environmentally compromised grows. A single harvest improvement often recovers a substantial portion of AC investment, with subsequent harvests representing pure profit from better growing conditions. For comprehensive setup advice, check our complete grow tent setup guide.

Integration with Ventilation Systems

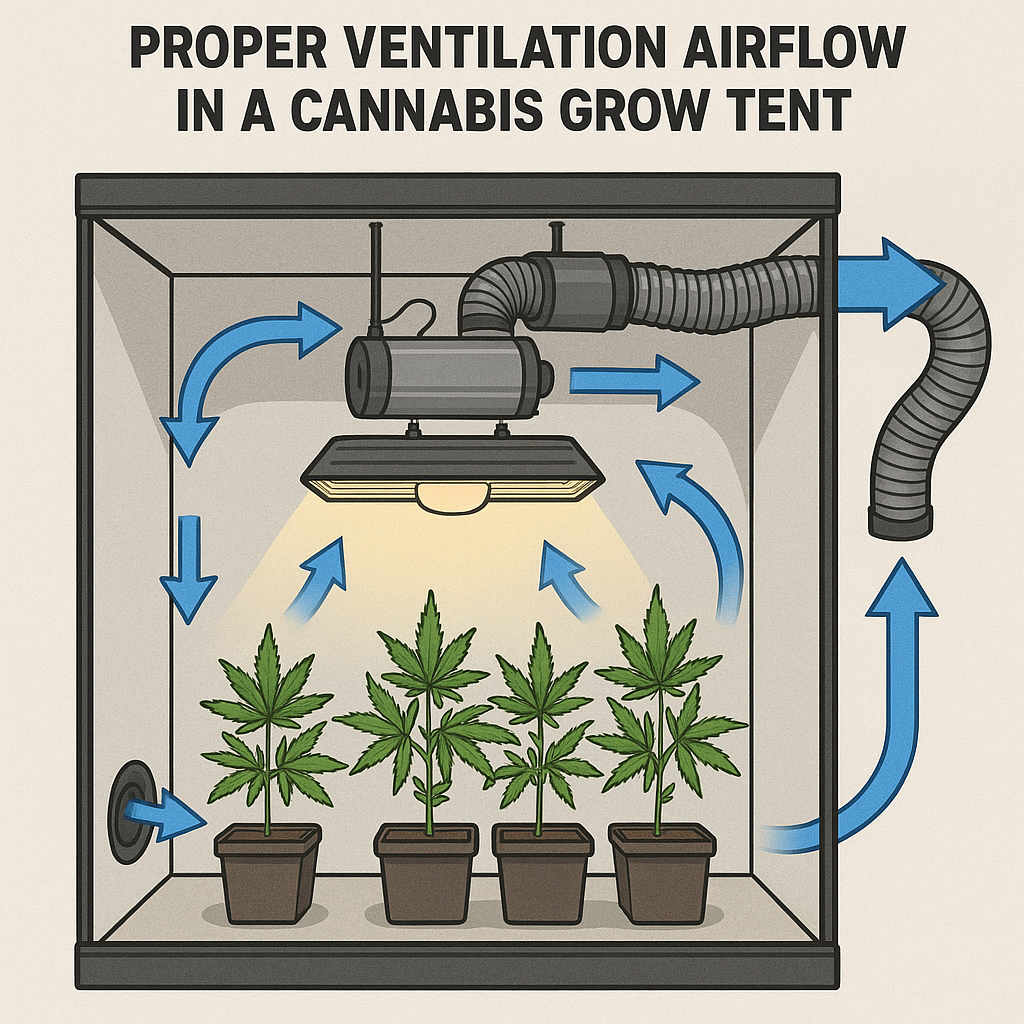

Complementary operation between AC and ventilation creates superior environments. AC handles bulk cooling and dehumidification while ventilation provides fresh air exchange, odor control, and air circulation. This division of labor allows each system to operate at peak efficiency rather than forcing ventilation to perform tasks it handles poorly.

Smart ventilation adjustment reduces wasted cooling. The Gorilla GXi Inline Fans automatically adjust speeds based on temperature and humidity readings, running at minimum necessary rates when AC maintains conditions rather than exhausting expensively cooled air unnecessarily. This intelligent coordination maximizes efficiency of both systems.

Sealed room advantages emerge with proper AC integration. Commercial growers often create sealed environments where ventilation provides only minimal fresh air exchange while AC handles all temperature and humidity control. This approach enables CO2 enrichment impossible in heavily ventilated spaces, dramatically accelerating growth rates and increasing yields. Learn more about proper ventilation in our guide on whether you need fans in grow tents.

Backup redundancy protects crops during equipment failures. Systems combining AC and robust ventilation provide mutual backup—if AC fails, increased ventilation can temporarily manage conditions until repairs are completed. This redundancy proves invaluable for commercial operations where crop losses from equipment failure cost thousands of dollars.

Noise reduction through lower fan speeds benefits home growers concerned about discretion. AC-maintained conditions allow ventilation fans to operate at lower, quieter speeds while still providing adequate air exchange. This reduced noise proves especially valuable for grows in living spaces where constant high-speed fan noise disrupts daily life. Read about quiet operation in our article on quiet inline duct fans.

Choosing the Right AC System for Your Grow

Mini-split systems provide optimal performance for dedicated growing spaces. These ductless units split cooling capacity between outdoor compressor and indoor air handler, enabling precise temperature control without losing precious vertical space. Mini-splits accommodate any tent size through various capacity models and offer zone control for multi-tent operations.

Portable AC units offer flexibility for smaller operations or rental properties where permanent installations aren't possible. While less efficient than mini-splits, quality portable units adequately serve single-tent setups and provide the advantage of easy relocation or storage. Choose models with dual-hose designs that don't create negative pressure by exhausting room air. For sizing guidance, see our guide on inline fan sizing for 4x4 grow tents.

Capacity sizing matters critically for adequate performance and efficiency. Calculate cooling requirements based on tent volume, lighting wattage (plan for 3.41 BTU per watt of grow light heat), and ambient temperature differential. Undersized units run constantly without reaching target temperatures while oversized units cycle frequently, reducing dehumidification effectiveness and shortening equipment life.

Smart integration with environmental controllers maximizes efficiency and crop protection. Modern controllers coordinate AC, fans, lights, and dehumidifiers to maintain optimal conditions while minimizing energy waste. The Gorilla GXi Temperature & Humidity Sensor provides laboratory-grade monitoring that triggers automatic AC adjustments maintaining perfect VPD throughout all growth stages.

Installation considerations affect both performance and operating costs. Proper AC placement ensures even temperature distribution without creating cold spots that stress plants. Professional installation of mini-split systems justifies costs through optimized performance and avoided warranty issues from improper DIY installations.

Advanced Climate Control Strategies

Automated temperature and humidity scheduling optimizes conditions for different growth stages. Seedlings thrive in warmer, more humid conditions (75-80°F, 65-70% RH) while flowering plants prefer cooler, drier environments (65-75°F, 30-40% RH). Smart AC integration with environmental controllers automatically adjusts targets as plants develop, eliminating manual intervention while ensuring optimal conditions throughout the lifecycle.

CO2 enrichment becomes viable with sealed-room AC systems. Heavily ventilated spaces exhaust expensive CO2 before plants utilize it, making enrichment economically unfeasible. AC-based climate control enables minimal ventilation sealed rooms where CO2 concentrations of 1200-1500 PPM accelerate photosynthesis dramatically, often increasing yields 20-30% beyond standard growing.

Heat recovery ventilation balances fresh air needs with efficiency in cold climates. HRV systems exchange stale tent air with fresh outside air while transferring heat between airstreams, providing necessary ventilation without the massive heat loss of standard exhaust systems. Combined with AC for humidity control, HRV creates exceptionally efficient year-round growing environments.

Zone control for multi-tent operations enables different environmental conditions in adjacent growing spaces. A single outdoor mini-split compressor can power multiple indoor units maintaining distinct temperatures and humidity levels for seedlings, vegetative plants, and flowering crops simultaneously. This flexibility proves invaluable for perpetual harvest operations requiring diverse environments.

Preventive maintenance ensures reliable performance during critical growing phases. Monthly filter cleaning, annual coil servicing, and refrigerant level checks prevent breakdowns that could destroy entire crops. Establishing maintenance schedules and keeping spare parts on hand provides insurance against the catastrophic losses that equipment failures cause.

Frequently Asked Questions

Is air conditioning really necessary for grow tents or can I rely on ventilation alone?

AC becomes necessary when ambient temperatures exceed 80°F, when high-intensity lighting creates unmanageable heat loads, or when you need precise humidity control during flowering. Ventilation-only systems work adequately in cool climates with moderate lighting, but AC provides dramatically superior results through temperature stability and humidity management impossible with fans alone. Most serious growers consider AC essential for consistent, professional-quality results. Learn more about temperature management methods.

What size air conditioner do I need for my grow tent?

Calculate BTU requirements using tent volume, lighting wattage (plan 3.41 BTU per watt), and desired temperature drop from ambient. A typical 4x4x7 tent with 600W lighting requires approximately 8,000-10,000 BTU capacity. Mini-split systems sized at the lower end of this range often outperform higher-BTU portable units due to superior efficiency and dehumidification. Oversizing reduces dehumidification effectiveness, so err toward proper sizing rather than excessive capacity.

Does air conditioning reduce humidity enough to eliminate the need for dehumidifiers?

AC provides substantial dehumidification—typically 2-4 pints per hour—often eliminating dedicated dehumidifier needs in smaller grows. However, large tents, dense plant canopies, or climates with extreme humidity may require supplemental dehumidification during late flowering when optimal conditions demand 30-40% RH. Monitor conditions with quality sensors and add dehumidification capacity if needed. Read our guide on bringing humidity down in grow tents.

Will air conditioning increase my electricity bills significantly?

Modern mini-split systems typically add $30-80 monthly to electricity costs depending on capacity, usage patterns, and local rates. However, AC often reduces total energy consumption by enabling slower, more efficient ventilation fan speeds and eliminating power-hungry dehumidifiers. The yield improvements from optimal conditions typically justify operating costs within a single harvest, with subsequent grows benefiting from increased production at minimal incremental cost.

Can I use a regular household air conditioner for my grow tent?

Standard household AC works adequately for grow applications, though systems marketed for growing offer features like enhanced dehumidification and remote monitoring valuable for cultivation. The key considerations are proper sizing, installation location enabling even air distribution, and integration with environmental controllers for automated operation. Avoid portable units with single-hose exhaust as they create negative pressure that disrupts ventilation systems.

Summary: Why AC Investment Pays Dividends

Air conditioning in grow tents delivers precise temperature control (70-85°F vegetative, 65-80°F flowering), automatic dehumidification removing 2-4 pints hourly, and environmental stability that increases yields 20-40% compared to ventilation-only systems. Modern mini-split systems achieve SEER 18-30 efficiency, often costing less to operate than running high-speed fans continuously while providing superior humidity management. The investment typically pays back within 1-2 harvests through improved yields, with subsequent crops benefiting from consistent professional-quality growing conditions year-round.

Create Your Perfect Climate-Controlled Growing Environment

Ready to eliminate temperature and humidity challenges from your growing operation? Air conditioning transforms unpredictable environments into precisely controlled growing paradises where plants consistently reach their full genetic potential. Whether managing summer heat, winter humidity, or year-round consistency demands, proper climate control separates amateur results from professional harvests.

Start with intelligent ventilation that works synergistically with your cooling systems. The Gorilla GXi Inline Fan Collection features AdaptiveAir technology that automatically adjusts airflow based on real-time conditions, maximizing efficiency while the GXi Temperature & Humidity Sensor provides laboratory-grade monitoring (±0.3°C accuracy) with automatic VPD calculations.

Build complete climate control systems with Gorilla Grow Tent Kits featuring superior 1680D canvas insulation that maintains AC efficiency, adjustable height accommodating equipment installations, and strategic ventilation ports enabling optimized airflow patterns. The legendary Gorilla construction supports heavy AC equipment while the reflective interior maximizes light efficiency.

Don't let environmental limitations restrict your growing success. Invest in professional climate control that delivers consistent results regardless of external conditions. Browse our complete collection of environmental management solutions designed by Northern California's elite cultivators for serious growers demanding exceptional results. With lifetime expert support, proven equipment, and intelligent automation, you'll create growing conditions that rival commercial facilities while enjoying the convenience and efficiency modern technology provides.

Transform your growing operation today with climate control systems engineered for reliability, efficiency, and consistently outstanding harvests. Your plants deserve optimal conditions—give them the professional environment they need to thrive. For additional resources, explore our guides on VPD optimization and fan positioning strategies.

Lena Myles

I'm a mushroom enthusiast and home cook based in Oregon. I'm passionate about foraging and creating fungi-focused recipes, especially delicious, plant-based dishes using gourmet mushrooms like trumpet, shiitake, and oyster. When I’m not in the kitchen, you’ll usually find me wandering the woods in search of new wild flavors.